Automated Storage and Retrieval Systems are just that – automated systems that efficiently and securely store items in a compact footprint. They also allow users to easily and quickly retrieve items when needed. Several companies manufacture a wide variety of self-contained, goods-to-person, automated storage and retrieval systems (ASRS).

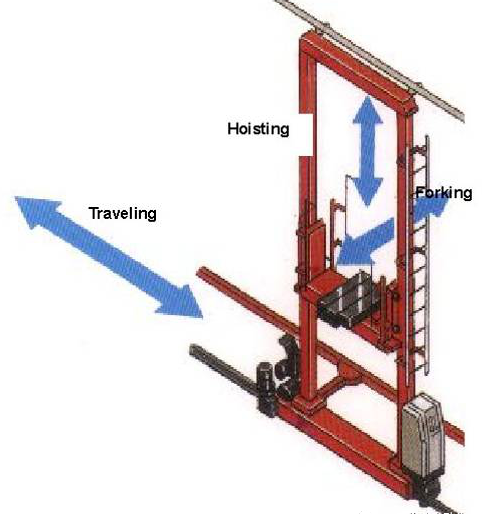

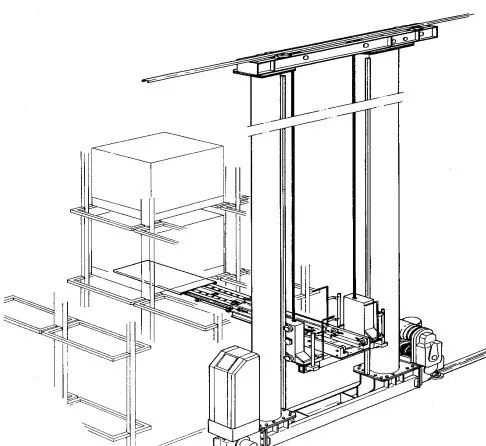

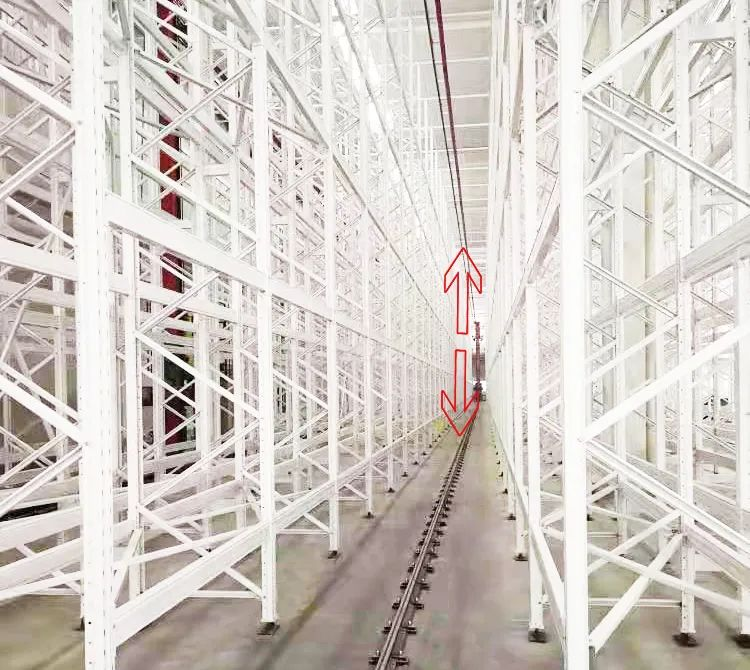

The stacker, also known as the stacking crane, can run back and forth in the aisle of the three-dimensional warehouse, and store the goods at the entrance of the aisle to the designated shelf position. The stacker is the iconic equipment of the automatic three-dimensional warehouse, and it is an important lifting and transportation equipment in the automatic three-dimensional warehouse.

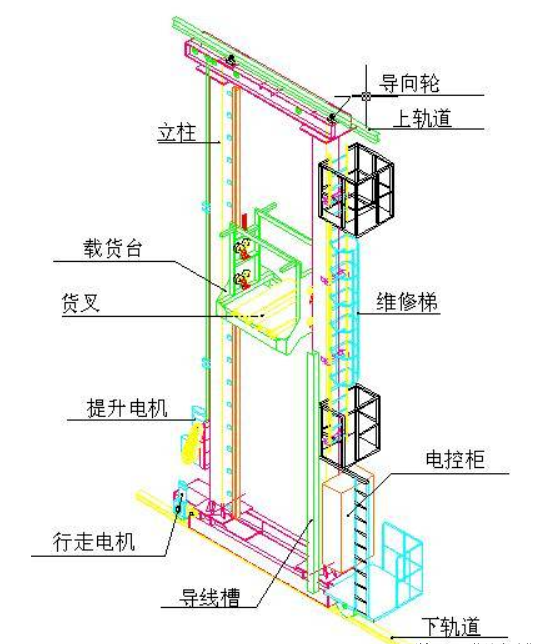

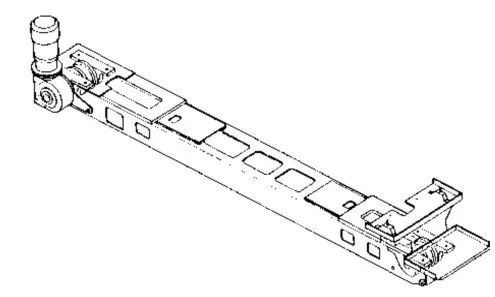

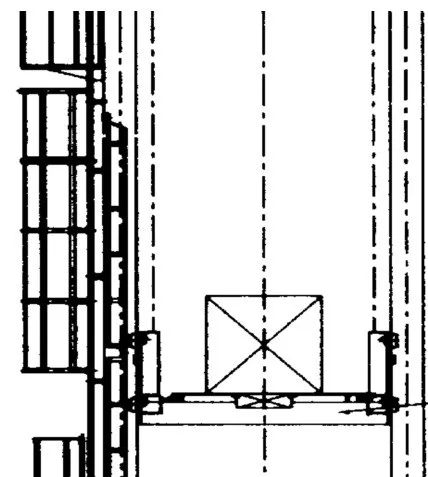

STACKER BASE the dynamic load and static load generated during the operation of the stacker are transmitted from the chassis to the traveling wheels, so the chassis is made of heavy steel as the main body welded or bolted to maintain good rigidity.

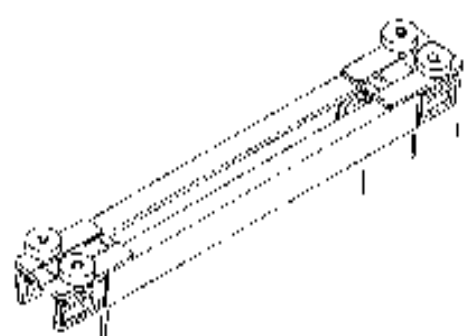

WALKING MECHANISM The running mechanism is also called the horizontal running mechanism, which is composed of a power drive device, active and passive wheel sets, and running buffers. It is used for the operation of the whole equipment in the direction of the roadway.

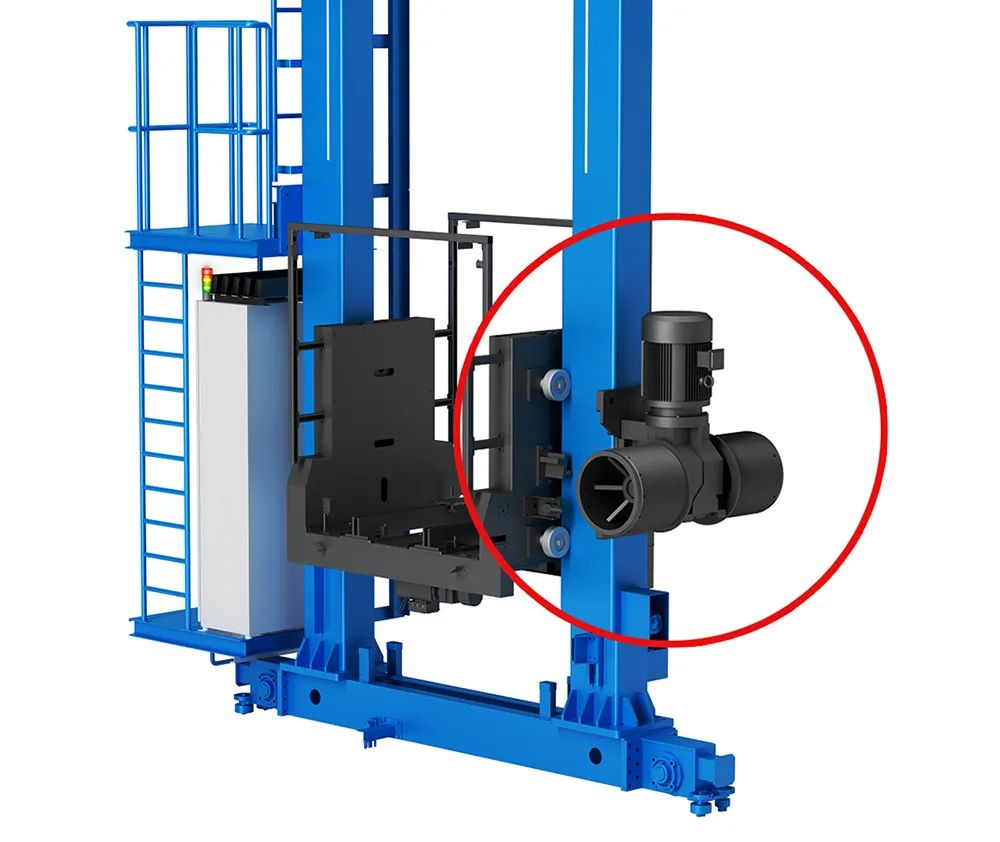

LIFTING MECHANISM The lifting mechanism of the stacker is also called the lifting mechanism, which is composed of a drive motor, a reel, a sliding group, a wire rope, etc., and is used to drive the cargo platform to rise and fall. Compact structure and reliable operation.

STACKER POST The stacker is a double-mast type, but its mast design is based on a high strength-to-weight ratio (High Strength-to-Weight Ratio) to lower the center of gravity to maintain stable operation; Side guide wheels, support and guide along the upper guide rail when walking; safety ladder equipped to provide the maintenance.

Top Beam The upper beam is on the top of the double column, together with the lower beam and the double column form a stable frame structure, the upper guide wheel can prevent the stacker from detaching from the upper track.

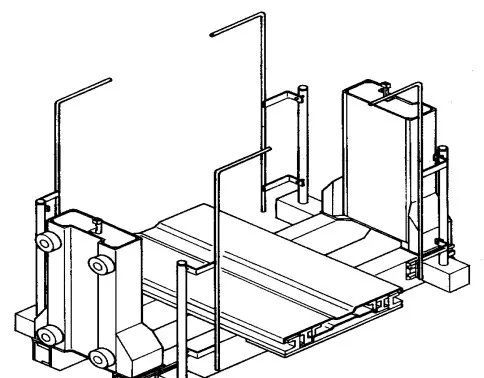

Loading Lift Platform The loading platform is the part of the stacker that accepts the goods and performs lifting movements. Located in the middle of the double columns, the lifting motor drives the cargo platform to move up and down. The loading platform is not only equipped with cargo over-length, over-width, and over-height detectors, but also cargo position virtual and real detectors to prevent out-of-tolerance or double storage of goods.

Fork The fork telescopic mechanism is a mechanism composed of power drive and upper, middle and lower tridents, which is used for the movement of goods perpendicular to the direction of the roadway. The lower fork is fixed on the loading platform, and the three forks are linearly extended and retractable through chain transmission.

Top Guide Rail&Bottom Guide Rail the guide rails top side and bottom side to make the stacker crane to walking along the guide rails.

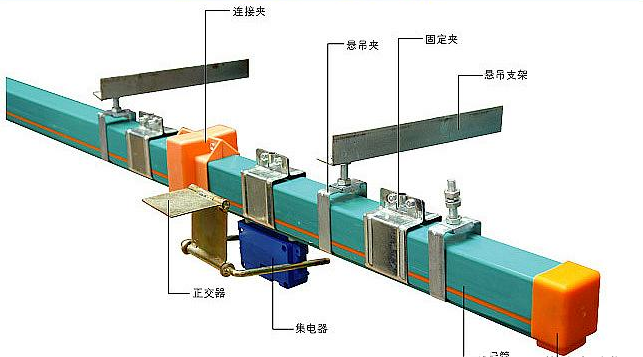

Power Guide Rail Located at the lower part of the shelf in the aisle of the stacker, it supplies the power supply for the operation of the stacker. For the sake of safety, the tubular sliding contact line is generally used.

Control Panel Installed on the stacker, built-in PLC, frequency converter, power supply, electromagnetic switch and other components. The top panel is a touch screen operation, which replaces the original operation buttons, keys, and selection switches. There is a standing position directly in front of the control panel, which is convenient for manual debugging of the stacker.

Post time: Feb-08-2023