Robots

-

1.5- 2.0T full electric pallet stacker forklift AGV automotive guided Vehicle

AGV is automatic guided vehicle. It is a type of forklifts,Which consists of an electronic forklift, KOB control system, navigation control system, wireless equipment and dispatch and control system.

-

Automatic Handling Forklift AGV Robot For Transportation Carriage

Automatic handling forklift robot is specially developed for line side transportation, library side transportation, low feeding and other scenarios, with newly defined products from the perspective of automatic handling forklift robot. The robot body is light in weight, large in load, which can reach 1.4 tons and small in working channel, providing customers with lighter and flexible automatic logistics solutions.

-

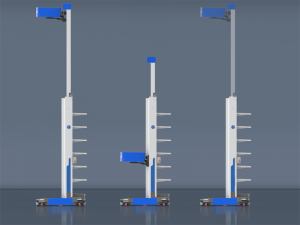

Double deep automatic picking robots for racking shelving

Double deep automatic picking robots for racking shelving is similar with multi layer automated ACR. But the most difference is the fork of robot can work ask VNA forklift fork to pick out of put in the left side case after complete the load and unload for right side.

-

Automated multi layer ACR for warehouse storage

ACR is the short of Autonomous Case-handling Robots, which is automated robots to carry the plastic toes or plastic containers to achieve the goods-to-person (G2P) automation model in a warehouse. In the system, the Robots walking in the warehouse with following the QR code navigation.

ACR system includes the ACR, intelligent charging pillar, racking shelving, multi function working station , WMS, WCS and relative internet hardware system.

-

2.5ton Electrical Automated Guide Vehicle

Automated Guide Vehicle is also known as AGV forklift and the forklift is self driving with the computer controlled. It also means no need forklift workers to drive the forklift to work in the forklift. when the worker give orders in the computer to operate the agv forklift. And the AGV forklift follows the instruction to accomplish missions automatically.

-

2ton automatic agve forklift for material handling equipment

AGV is the short name of Automatic guided vehicles, which is similar with the traditional and standard forklifts. The agv forklifts can move automatically following a route that has been set out or programmed in advance. It is controlled by the wire guide system.