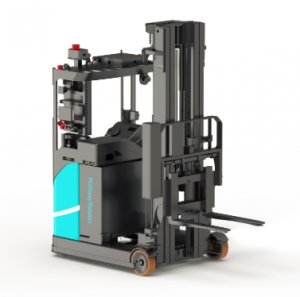

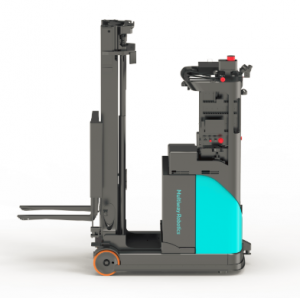

Automatic Handling Forklift AGV Robot For Transportation Carriage

Product Introduction

Automatic handling forklift robot is specially developed for line side transportation, library side transportation, low feeding and other scenarios, with newly defined products from the perspective of automatic handling forklift robot. The robot body is light in weight, large in load, which can reach 1.4 tons and small in working channel, providing customers with lighter and flexible automatic logistics solutions.

How did the Laser guidance AGV work?

LGVs are AGVs with Laser Navigation Triangulation. In the warehouse using a laser positioning system to navigate the way. They have one or more two-dimensional navigation lasers, which are referred to as either a Navigation Device or Laser Emitter. These navigation lasers are elevated anywhere from 10 to 15 feet in the air and spin at several revolutions per second. These reflectors can be either flat or cylindrical, both of which have their own benefits and advantages. The LGV uses the signals it receives from the reflectors to triangulate the vehicle’s position. Depending on the manufacturer, some devices will calculate and correct their positioning 30 to 40 times per second. This makes them highly accurate and reduces the need for corrections.

Why Choose Ouman AGV forklift?

1, Ouman has full experience in the AGV forklift and all the automatic warehouse racking and handling system.

2, We have completed many successful projects in domestic markets and oversea markets.

3, With the use of AGV forklifts, the overtime working time and turnover costs will be improved.

4, High accurate AGV reduce the damage caused by forklifts trucks.

5,Potential savings associated with lights-out operations.

What the advantages of AGV forklift have?

• Quick and easy to install. The installation isn’t invasive, either. All you’ll need to do is place reflectors around the facility.

• Incredibly accurate. The positioning algorithms are very advanced and allow for a position accuracy of + 5 mm.

• Fast to move.A high-speed LGV can reach up to 6.5/sec.

• Easy to maintain. Regular maintenance is to keep the reflectors clean.

• Easy to modify. To change the route by modify the software.