China automatic four way shuttle supplier for warehouse storage

Product Introduction

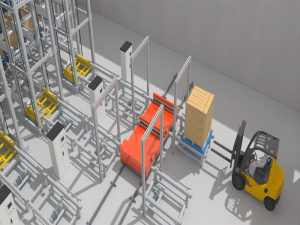

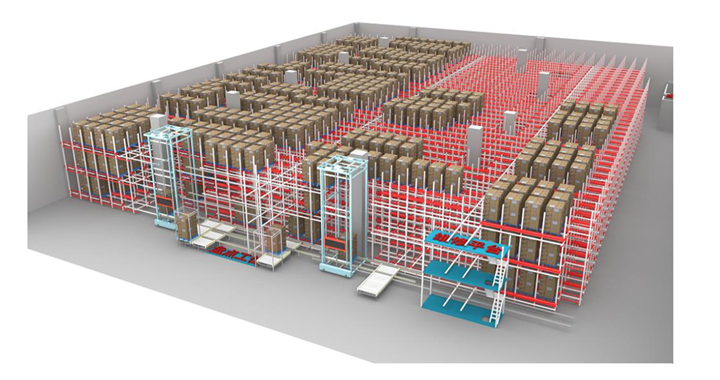

Four way radio shuttle system is automated high-density storage and retrieval system for the handling of palletized goods.The intelligent four-way shuttle racking system with intelligent robots for automatic access to goods and cloud-based warehouse management software provides customers with "automatic four way shuttle + automatic racking system" intelligent storage solutions to meet the different storage needs of customers' boxes or pallets, throughout production.

Four way shuttle advantages

Why four way shuttle racking used in the warehouse?

● Intelligent four-way shuttle racking system is an automatic solution which it can run in any direction along the longitudinal or horizontal track on the cross track.

● Four way shuttle owns the functions of climbing and automatic leveling, and can standardize the system configuration because it can drive in both directions.

● The core functions of the intelligent four-way shuttle racking system are: the four-way shuttle is mainly used for the automatic handling and transportation of pallet goods in the warehouse, automatic storage and retrieval, automatic lane change and layer change, intelligent leveling and automatic climbing, and directly reaches the warehouse any position.

● It can be operated on the shelf track or on the ground, without being restricted by the site, road and slope, fully reflecting its automation and flexibility. It is an intelligent handling equipment integrating automatic handling, unmanned guidance, and intelligent control.

● The intelligent four-way shuttle racking system, logistics management system (WMS), conveying system, vertical lifting system, etc. developed by us are committed to building a comprehensive intelligent warehouse integrating informational, automation and intelligence for customers' warehouses.

Our Service

Why ouman is your best choice for automatic solution supplier?

● Ouman has our own four way shuttle and two way shuttle for racking system and what kind of goods are suitable for four way shuttle storage system.

Goods package type: Pallets

Goods dimension(mm): W1200-1300xD1000-1200mm;

W1400-1600xD1000-1200mm.

Good weight: <=2000kg

Operation height <=15m

● Ouman has a full skilled technical engineer design team and we can provide the best service for racking system.

Free design could be provided with the following information.

Warehouse storage area Length____mm x Width____mm x Clear height___mm.

Warehouse’s door position for loading and unloading goods.

Pallet Length____mm x Width____mm x Height___mm x Weight_____kg.

Warehouse Temperature_____Degrees Celsius

Inbound and outbound efficiency: Quantity of pallets per hour_____.

● Every shuttle will be tested before sending goods and also during the installation, ouman also provides the online service and onsite service.

● We provide one year at least warranty for customer.

Warranty is one year. Fast response within 24 hours for overseas customer. Firstly test online and adjust ,if couldn’t repair online , engineer will go and solve the problems on site. Free spare parts will be supplied during the warranty time.