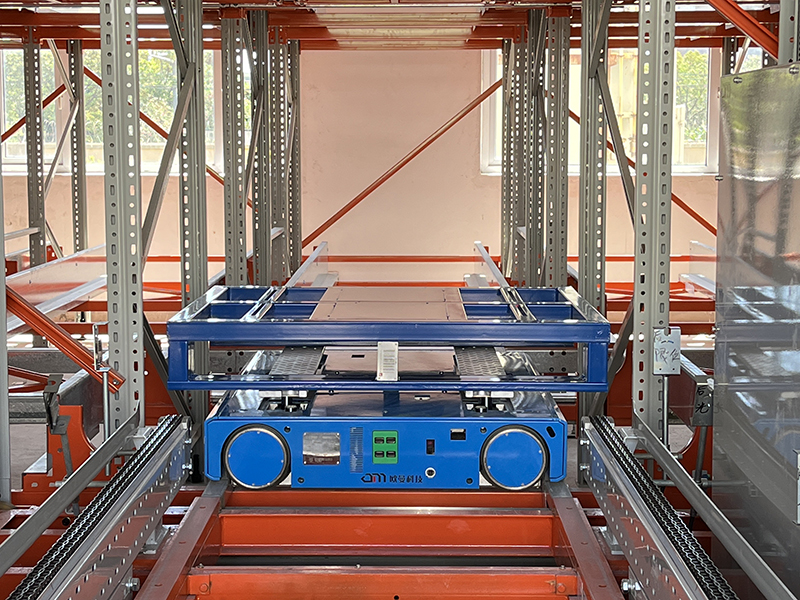

Four way radio shuttle racking for asrs warehouse storage racking system

Comparison of four way shuttle racking & ASRS

|

Item Comparison |

ASRS |

4way shuttle racking system |

|

Suitable warehouse |

20m length at least |

High,low and old warehouse |

|

Flexible Layout |

Single/double deep |

Add radio shuttles |

|

Failure Loss |

Crane broken, whole aisle stops |

Shuttle error,other shuttles work |

|

Storage Utilization |

Low storage utilization |

High storage utilization |

|

Invest cost |

High cost |

Low cost |

|

Energy consumption |

High |

Low |

|

Working limit |

Stacker crane only work one aisle |

Shuttle can work all pallet postion |

|

Working model |

FIFO&FILO |

FIFO&FILO |

|

Maintain cost |

High |

Low |

|

Shift |

Shift with conveyor system |

Shift easily |

Comparison of four way shuttle racking & standard pallet racking

|

Item Comparison |

SPR |

4way shuttle rack |

|

Warehouse type |

Normal warehouse, forklift use |

High automatic warehouse |

|

Storage utilization |

Low |

High |

|

Working Efficiency |

25pallets/hours |

25pallets/hours but add shuttles |

|

Warehouse operation |

Manual operation |

Automatic operation |

|

System reliability |

Manual operation, not very reliable |

Multi shuttles work together,reliable |

Required information

1.Pallet size: Length, width, height

2.Pallet type: plastic pallet, wooden pallet or steel pallet

3.Warehouse working time: how many hours for warehouse works

4.Inbound warehouse working efficiency

5.Outbound warehouse working efficiency

6.Working models: FIFO or FILO

7.Required storage pallet positions

8.Warehouse size: length, width and height

9.Cargo size and weight

10.Cargo type on pallet: any multi kinds of cargoes on the pallet

11.SKU quantity

12.Single SKU quantity

13.Distribution area set in the warehouse or not

14.Load&unload models for cargoes

Project case

Garment Industry

The warehouse located in the east of China. The main products are garment materials.

Basic information of warehouse & product

1)Warehouse size L57000mm*W48000mm*H10000mm

2)Cargo with pallet size: L1200*D1000*H1500mm

3)Cargo with pallet weight: 1000kg/pallet

4)Working efficiency: 160Pallets/Hour

Designed drawing

1.Storage pallet position: 5584 Pallet Positions

2.Pallet positions for AGV forklift: 1167 Pallet Positions

3.Vertical forklift quantity: 4pcs

4.Four way shuttle carts: 5 radio shuttle carts

5.AGV forklifts used together with conveyor system and racking system.